First problem

June 2021

It wasn’t entirely unexpected, but after three and a half years the first problem with the Thing appeared…

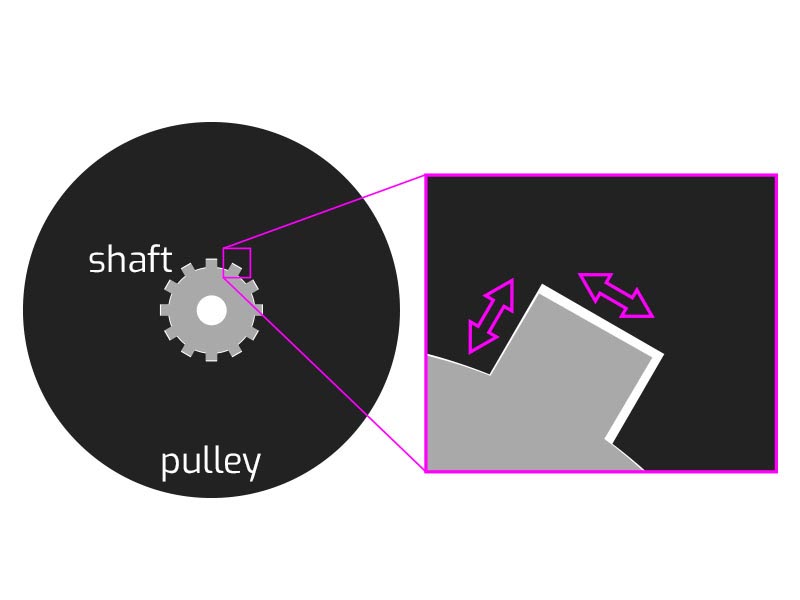

But first, some context. The Spyder’s final drive system is belt-driven and made up of two pulleys: the first on the transmission shaft (smaller), and the second (much larger) on the rear wheel.

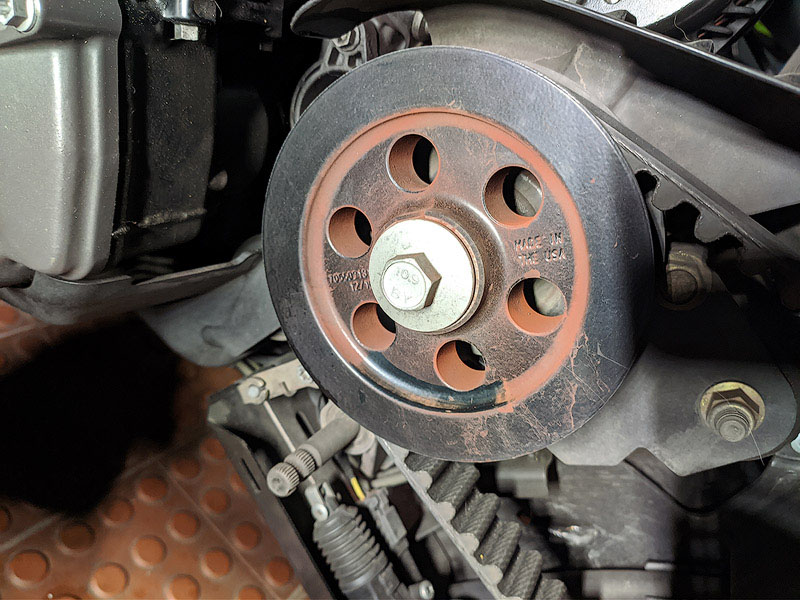

Reports of issues with the front pulley (on the transmission shaft) have long appeared on the American forum. The first symptom is that it begins to get covered in a reddish dust (rust), nicknamed the “red dust of death.” The final stage comes later (after quite a few miles/kilometers), when the pulley fails and the transmission shaft spins freely, leaving the Spyder completely immobilized. There isn’t really a consistent pattern: a few rare cases fail below 6,214mi10,000km, most around 15,534mi25,000km, and at least one case occurred at 52817mi85000km. Some theories suggest that a belt tensioner (not fitted from factory) might mitigate the problem, but there’s no certainty.

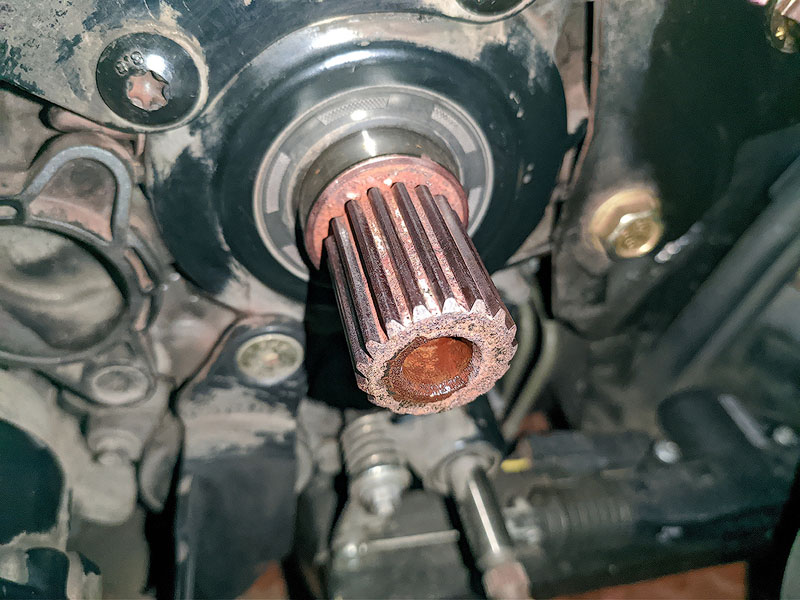

So what causes this phenomenon? Technically it’s called fretting, best translated as “corrosion by friction.” The transmission shaft engages the pulley with a splined profile. The fit is tight but inevitably subject to micro-clearances. With the shaft turning under considerable torque, these tiny gaps cause movement and friction. Since both surfaces are metallic, this friction causes wear, particularly inside the pulley, which seems to be made of a weaker alloy. Fortunately, replacing the pulley is far less costly and complex than replacing an shaft. The reddish dust seen outside the pulley is ferrous oxide or rust particles resulting from this wear. Once the process begins, the inner spline of the pulley slowly wears down until the profile is flattened, almost toothless. At that point the shaft no longer grips, spins freely, and no rotation is transmitted — leaving you stranded.

Interestingly, this isn’t rare in this type of transmission (it also happens on Harleys). The manufacturer is fully aware of the issue and likely considers the pulley a wear item, though they replace it under warranty if failure occurs.

I was well aware of this problem and had been doing routine checks every 3,107mi5,000km. At the last inspection in April, the pulley looked as shown in the photo.

With nearly three years gone and warranty expired, I had no choice but to tackle the job myself. I could have handed it to the dealer, but being well informed I decided to do the replacement myself. The Spyder was manufactured in 05/2018, and at that time no lubricant was applied to the shaft during assembly — hence the result. More recently, BRP's began using (and recommending) Kluberpaste 46 MR 401 on the spline. It’s a high-pressure lubricant which, according to experts on the American forum, works but isn’t water-resistant, meaning it must be reapplied regularly. Specialists (mechanics and engineers with years of experience) instead recommend a molybdenum-based lubricant. Molybdenum is a mineral with low solubility in water, the sixth element with the highest melting point (3,925ºF2,163ºC), very low thermal expansion, and immense tensile strength when reduced to tiny particles. I found two suitable lubricants: Loctite LB8012 moly paste anti-seize and Honda M-77 assembly paste. The first is only sold in half-kilo tubs at a crazy price. The second is used by Honda dealers in all shaft-drive transmissions (e.g., Pan European, Goldwing). It comes in 2.65oz75.00g tubes, not cheap (€34.95), but the most appropriate for this case.

I called a local Honda dealer, but it went badly — they acted like I was asking for something imaginary. I quickly gave up; maybe they assemble shafts with cooking oil there… Irony aside, when the customer has to explain the product to the seller, something’s wrong. I turned to Google and found the tube on a Dutch site specializing in *Honda materials. A week later, the precious tube was at my house.

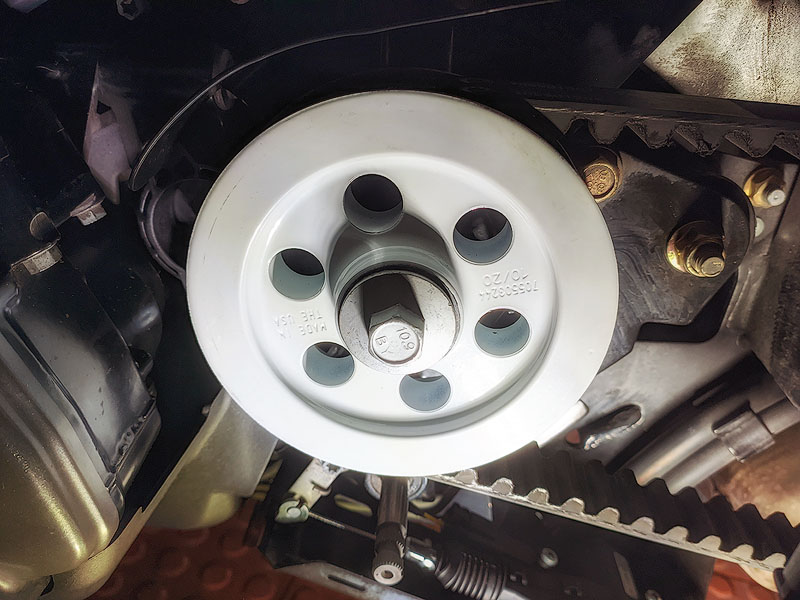

Even before that, I had ordered the parts needed for replacement: a new pulley and a tightening bolt (ref. #250001017), which the manual says must always be replaced with the pulley. There was also news about the pulley itself. From September 2020, the manufacturer introduced a new model (ref. #705503239), easily identified because it’s painted white (instead of black like the old ref. #705502134). From what I researched, the redesign wasn’t due to this problem but another that appeared on the new Spyder RT — a whistling noise at certain speeds. Apparently, air pockets formed between pulley and belt in the old design, causing an irritating whistle. It was very noticeable on the RT, though I never noticed it on the F3-S. I ordered from Benimoto, who promptly replied that the parts were ordered but the new pulley wasn’t in stock and had to come from the factory in Canada — estimated delivery end of April, about three weeks. After three weeks, still no news… I wasn’t too worried since I had checked there was no play, so it was safe to keep riding. Later I learned the reason: the new pulley was out of stock at the factory, only available from early June. By mid-May I hoped my April order would arrive sooner… and it did! On May 21st I had it at home with the bolt. Exactly 44 days and €202 later (pulley, bolt, and paste), I had everything needed.

Six weeks is a lot, but likely due to being out of stock. I’ve ordered factory parts before that arrived in just over two weeks, which is reasonable. Still better than waiting two months for Japanese factory parts in the past. In my experience, Triumph was the best — everything delivered within a week.

The replacement was easier than expected. First, lift the rear wheel and rotate it to slip the belt off. The old pulley came off without a fight, probably because I didn’t let the situation reach the worst stage. I’ve read reports of pulleys needing to be heated with a torch, pulled with extractors, or even broken apart. In my case, a little WD-40, let it act, and pulled it off by hand. The transmission shaft had no damage, as is usually the case. It’s made of a strong alloy, unlike the pulley material — thankfully.

Then it was a matter of cleaning the shaft thoroughly with proper fluid and a wire brush, lubricating the spline with the Honda wonder paste, fitting the new pulley, and tightening the bolt to the recommended torque — which was recently revised (probably due to this issue) from 92ft-lb125Nm to 111ft-lb150Nm. I also marked it to check in the future if the bolt stays put. Finally, refit the belt by pushing it onto the rear pulley while rotating the wheel. No belt adjustment was needed since the wheel hadn’t moved and the new pulley has the same dimensions as the old one. For peace of mind, I checked belt tension, which of course hadn’t changed.

Everything was simple, quick, and done with the materials I wanted.

As I said, this is a well-known problem with Spyders, so it didn’t catch me off guard. Still, €200 in parts is unpleasant…

I’m still unsure whether to fit a belt tensioner, supposedly to reduce pulley jolts and thus the fretting phenomenon. For now, I’ll keep monitoring and hope the special racing lubricant does its job and prevents destruction of the new pulley

Messages:

Posted on 2022-11-25 by ZuluEcho

Posted on 2022-11-25 by Daniel Santos

Leave a message